Lawson Development

The Lawson Way development is progressing with the bricking-up of the south wall. Keep up to date with changes at Lawson Way by viewing the photographs below which will be added to as the changes are made.

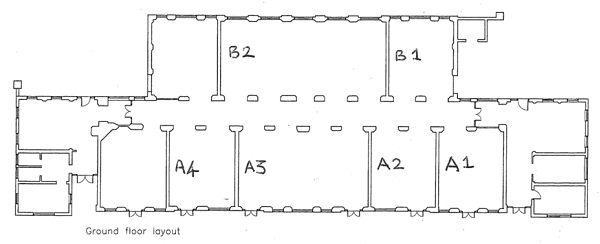

Original building layout

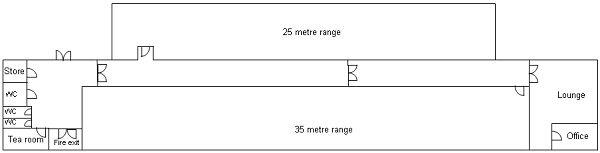

Planned building layout (not to scale)

The average number of people working each Saturday is 9

February 2016

Almost there

January 2016

Three more fire doors required. The concrete plinth has been laid in front of the backstop floor baffle has been constructed. At the bottom of the disabled acccess ramp at the front entrance we have dug out a landing area and mixed over 2 tonnes of concrete. Just inside the doors we have had to remove recessed carpet frames and fill them with concrete to remove the trip hazards. Two hundred metres of skirting and coving fitted.

November 2015

Attention is now turned to the West end of the building where we have renovated the emergency door and poured a ramp.

|

|

The ramp at the front door has also been worked on

and the corridor fire doors have been hung

October 2015

Work has been carried out to install fire doors, plaster areas damaged by water ingress, fire damage and vandalism, install skirting & coving and the last remaining boarded up windows in the building have been bricked up. The handrails for the access ramp have now been installed. In A-Range the air intake system is being installed.

September 2015

January 2015

Ceiling is 90% boarded and the extraction ducting has been completed therefore allowing the last section of ceiling to be worked on. Work is underway to board out the corridor and we have obtained three sets of double fire doors to be installed.

November 2014

Now that the kitchen is out of the way, work has started on bringing the gents toilets into a more acceptable condition (though they have been useable for a long time). The ladies and disabled toilet facility is part of the funded facility and will follow in 2015.

October 2014

The kitchen has been completed, water heater installed and a steel grill installed at the window. Geoff Bell has even been cooking in it.

September 2014

The closing off of all of the windows on the north side of the building has now been completed, as well as allowing the work on B Range to step up a gear this also makes the building look more presentable and improves the building security.

August 2014

Brackets have been made and steel baffles have been installed to protect the ceiling from errant projectiles. The steel baffles have then been faced with timber which will eventually again be faced to further protect the steelwork.

May 2014

More work on the kitchen and we now have units fitted and a working sink though the walls still need finishing.

We are now waiting for the builders to start with the major work to be carried out on B Range but, once started, that work may hold up progress on A Range .

April 2014

A team of electricians has now given us permanent lighting in the range to replace the temporary installations. Drywalling of the walls has continued and we are more than 75% boarded out going down the range with the significant deficiencies being the fist section near the door (more brickwork required) and at the backstop (more ceiling work required).

March 2014

Covering of the section walls has been completed and plywood coverings have been applied. Plasterboards are being applied to the walls and sections without thermalite block are being insulated before the application of the boards so that sound reverberation is prevented. The kitchen window has now been removed and a double-glazed unit has been put in its place

February 2014

Each of the wall sections which support the beams has been clad with wooden sleepers and we have started to board over the sleepers with 1" thick ply. The kitchen window now has a roller-shutter installed. The ceiling sections now have walkways installed to allow access for maintenance.

January 2014

The Linatex curtain has now been put into place and the baffles down the range have now all been timber clad to protect the masonry and prevent ricochet. B Range has been cleared to allow the removal of the cross-walls. The two RSJ's to be put in place when the walls are removed have been cut to the required length.

November 2013 Timber has been placed above the backstop to prevent damage to the brickwork from stray shots. The front of the backstop has been boarded.

October 2013

Lighting has been provided in the central corridor in preparation for winter's shorter days. A platform has been built to take the large extraction fan and the path out of the building for the exhaust is being worked on. Steelwork is put in place to accept the steel plates that will form the roof of the bullet catcher and the timber frame for the wooden facing of the canopy is under construction.

|

|

|

September 2013

The work on the suspended ceiling continues and the toilet area is being boarded out. Two of the armoury doors obtained from Brambles Farm TA Centre have been installed so that the range is a secure lockable area.

|

|

August 2013

Work has resumed on the kitchen.

The steel beams having been encased in flame retardant plaster board and being protected with several inches of timber to prevent penetration & splash back. Further work is being carried out on the backstop.

__41__.jpg)

__45__.jpg)

July 2013

A major stage in the construction has started with the erection of the significant steelwork which will form the bullet catcher. The vertical plates, each weighing 300kg have been carefully lifted into position and bolted & resin bonded to the concrete.

|

|

June 2013

The toilet area ceiling has been steel reinforced, lights and a hand dryer installed. The kitchen walls have been prepared for boarding out and additional lighting been installed to help with the construction work. The base of the bullet catcher has been leveled and bolted into position ready for the vertical plates to be lifted into position. Work on the ceiling in section 5 has been halted to allow the steelwork to be brought in. The steel beams are being clad with fire retardant board and intumescent mastic before being protected with timber.

April 2013

We now have light fittings after a great Ebay purchase, these will go above the firing points at 10m, 15m and 25m but will need to be boosted by long fluorescent lights (yet to be sourced) behind each of the walls down the range.

Work has commenced on ceiling section 5 of 6 and the next stage of backstop construction has started. The concrete wall has been clad with the timber which will reduce reverberation and cushion the movement of the steel plate, Next, 12mm thick steel plate will be bolted through the timber into the concrete.

March 2013

Work continues on the ceiling. We have obtained railway sleepers from Peter Brown to help form the backstop, removed the plaster from the toilet walls (fire & smoke damaged areas to be replaced) and removed the ceiling from the store so that we can reinforce the roof.

February 2013

A distribution board has been installed at the east end of the building (office end). The light cabling has been stripped out and replaced with a heavier cable to feed the distribution board and a ring main has been installed to provide 240V sockets in A range.

January 2013

The last section of internal wall running along the corridor has been filled and the range "box" is now complete, entry to the A Range can only be made through the two doorways. With great thanks to Ken Marsden now have ample steel for the backstop.

Construction of the backstop wall is now complete. The wall is 440mm thick and use around 800 blocks to take it to the full height and width required. The wall will be timber clad before the steel plate is fixed into place. The top of the wall will support the ceiling beams.

The burned-out kitchen area has has further attention, lighting has been installed and the kitchen furniture moved in (only to give us space to do work elsewhere). The kitchen will be tiled before any permanent units are installed.

December 2012

The foundations (6.5 metres wide and 1 metre deep) for the backstop have dug out and the concrete has been poured but there has been no progress on the backstop as we need a brickie. The last beam put in place has now been bricked into position and the timber beams have been lifted into place and we can now make progress on thesuspended ceiling which is 30% complete. Some cabling work has been done and we have a few bulbs to lighten the work.

October 2012

We are now digging foundations for the backstop which will stand separate from the back wall of the range. The steelwork will not be supported by the external wall of the building as other clubs have been found to suffer from bellying walls.

September 2012

Building Control came in to check that they were happy for the beam to be installed. Once permission was granted, a Genie was hired and the beam was installed.

The beam has caused us a significant delay but now we can continue with the ceiling and following discussions with Building Control we now have a plan for the backstop which will not rely on us fixing the steelwork to the back wall.

August 2012

The electricity has been connected! The plans have been redrawn (again).

July 2012

The cable is now in place but the meter cannot be connected as the installers want an earth point 9m from the meter. A cable has no been installed and earth rods sunk into the soil. We are now waiting for the meter installers to come back.

The burnt out room which will hold the kitchen has been the subject for some more attention this month. The fire caused the wall to crack and bulge at the seat of the fire and the window melted and warped. The damaged brickwork has been removed and the whole wall section has been rebuilt.

The brick pillars are now complete so that the beam can be put into place but the plans have to be re-drawn to show the change to the building.

June 2012

In preparation for the electricity connection, we have drilled through the floor into the basement and out from the basement to the trench which has been dug to take the cable from South Bank Road onto the site. Peter Cooper has installed distribution boards ready for the connection of the cable.

The burnt out room which will hold the kitchen has been stripped of all plaster to get back to the bare brickwork.

The drains have had a lot of attention and, finally, we have water flowing freely from the site. Rodding and jetting took a significant amount of time but now even the cellar has drained.

May 2012

A lot of the work taking place recently has been the brickwork. The span across the largest classroom is too big for timber beams to be installed. This has meant that the suspended ceiling could not be completed without the installation of another girder to be installed to divide the span into two sections. A girder was purchased and brought onto site, two large holes were dug and foundations laid for brick pillars.

The drains which have been a constant blight have been finally cleared by Northumbrian Water. All of the drains on the estate have been clocked up and have backed up to ours because of a problem which had been caused during the land clearance at the back of the industrial units. Now that the drains are cleared further down the system we have to tackle the problems on our own site which are due to silting-up.

March 2012

Over 25 tonnes of rubble have now been bagged and dragged out of the building, if you need rubble then come get some!

February 2012

December 2011

In preparation for the impending bad weather, all of the concrete and Thermalite blocks have been hand-balled inside the building to prevent them being damaged by frost and ice. Many of the blocks are wet and heavy due to the heavy rains. The blocks have been stacked near the old doors and windows to make it difficult for night callers to gain entry into the building.

The broken window panes on the north side of the building have been removed and have been replaced with perspex to stop the ingress of rain etc and this has resulted in a significant reduction in the noise level inside the building.

November 2011

October 2011

The ceiling starts to take shape

The missing window glass on the North side of the building, over 70 panes, has been replaced with polycarbonate during the summer and this has improved the appearance of the building, reduced the noise level from the A66 and stopped the ingress of wind and rain. Hundreds of breeze blocks have been moved into the building, via wheelbarrow, to get them indoors before the bad weather arrives. The brickwork at the backstop end of the range has been completed but is not shown here because it is totally dark at that end.

May 2011

Blockwork in the shooting area and the first section of the downrange walls have now been completed, as shown below. The image shows the framework for the suspended ceiling being constructed.

April 2011

The drive now is to line the interior walls with concrete block work, much of which has to be insulated for both heat and sound. This means that there is not much to see on the outside of the building. The interior work also restricts the amount of daylight available so the photographs are now a little greyer.

January 2011

This sign has been erected temporarily to show that the building is occupied. We will not put the correct signage up until the building is more secure. The windows on the north wall are boarded over but not impregnable. A strongroom inside the building will allow secure storage of some materials in case the building is visited by... er... non-members of the nocturnal kind.

Wall A1 has now been removed making the gallery 35 metres long and materials are now arriving for the interior brickwork and blockwork. for the inside walls of the range.

__32__.jpg)

__25__.jpg)

__28__.jpg)

__29__.jpg)

__28__.jpg)

__39__.jpg)

__27__.jpg)

__35__.jpg)

September 2010

The south wall is now being bricked-up, this will allow the "A" range to be made useable.

July 2010

In recognition of his outstanding efforts and unstinting dedication for the Lawson Way project, Hon Treasurer Peter Metcalfe is presented with a Mauser rifle, with suitable engraved brass plate, by Richard Frankland and Dave Pengilley on behalf of the committee. Without Peter's dedication we would not be in the position we are now regarding this prestigious venue.

__35__.jpg)

June 2010

__21__.jpg)

___d0066b5d09eb4cbbb4f5545c01963076(400x300)__23__.jpg)

Here lad... this is how to be a stirrer

May 2010

Delivery of steel beams to allow removal of more internal walls

__35__.jpg)

__50__.jpg)

__42__.jpg)

__54__.jpg)

__52__.jpg) (who he?)

(who he?)

February 2010

__35__.jpg) The main gallery which will become the rifle range

The main gallery which will become the rifle range

__21__.jpg)

Left to right.... walls out and archery bosses go back another 10 yards.....

__37__.jpg)

__34__.jpg)

The long corridor running along the centre of the building.

The long corridor running along the centre of the building.

Drilling Bore holes in June 2009

Drilling Bore holes in June 2009

The Corner

Here is the Southeast corner of "A Range" and how it is changing.....

__12__(@0x300).jpg)

__18__(@0x300).jpg)

__43__(@0x300).jpg)

__22__.jpg)